Roll Forming | Metal Fabrication

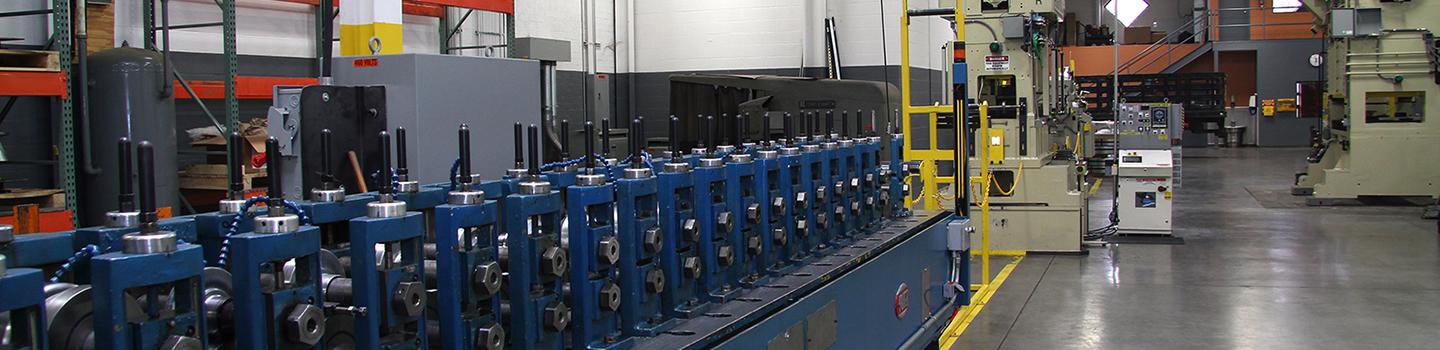

Roll forming is a process by which sheet metal is given a custom shape after passing through a series of rolling dies. Roll forming operations have long been a firmly established facet of ForMasters’ business, and, as with other facets of our operations, ForMasters has embraced innovative roll formed technologies and design and build for a wide variety of different shapes, from very simple to complex.

Roll Forming is Often an Option for Producing Parts When:

• Uniform shape over long pieces, a roll former is required.

• Close tolerances over long pieces must be maintained.

• Strength must be added to function.

• Cosmetic appearance is taken into account when roll forming steel and other metals.

• It produces parts free of the die or press marks, thus reducing further processing, time, and expense.

• High-speed production using roll forming for large orders reduces the cost per part compared to other processes.

Pre-Punched Roll Form Parts

ForMasters specializes in complete in-line processing. The material to be formed runs through a complex process wherein intricate cutouts or many holes with irregular patterns may be pre-punched with computerized accuracy. From there the material proceeds directly to the roll former, where, through a series of rolls, it is brought progressively to its final shape. The roll form shaped material is then cut off to precise lengths–again with computer accuracy–thus eliminating in many cases the need for secondary operations. In addition, pre-punching allows for cutouts that may be impossible to achieve after the shape has been formed.

ForMasters has been at the head of the industry in pre-punching roll formed parts and can thus offer expertise in this area unavailable elsewhere.

ForMasters Roll Forming Offers:

• Moldings

• Channels

• Angles

• Custom shapes

Secondary Operations, Such As:

• Secondary bends

• Painting and powder coating

• Secondary punching

• Welding

• Plating